What variables affect pitch performance?

The secret to producing great pitches is to understand how they play, why they play that way and what can be done to improve the way they play.

Depending on the speed of the delivery and bowler the ball will be in contact with the pitch for between 1.7 and 3 thousandths of a second. That means in a 50-over a side game the performance of a pitch will be judged on between 1 and 2 seconds of ball-surface interaction! This might not appear a long time, but it does represent 600 impacts of the ball into the surface – each an event in which the pitch performance counts.

So what is going on in those few thousandths of a second that the ball is in contact with the pitch? The interaction is complex and even subject to scientific study but essentially the ball hits the surface, deforming itself and the surface slightly, and then rebounds towards the batter and the stumps. During the interaction, the ball loses about 10% of its speed (on slow pitches it loses more, on qquick pitches it loses less) and exits at a less steep angle than it went in.

In terms of the pitch, the amount of loss in speed and the angle of exit are functions of how hard the pitch is (how much it deforms), the smoothness of the surface (affecting the exit angle) and the friction between the ball and the surface.

Pitch hardness is determined by:

- The soil the pitch is constructed from.

- How well that soil is compacted.

- The moisture content of the soil

- The amount of thatch in the profile (this acts like an energy/shock absorber, reducing pace and bounce)

- Whether there are any breaks in the soil profile.

- The grass, although grass has a relatively small effect on hardness during ball impact.

Pitch smoothness is determined by:

- The original construction levels.

- The effectiveness of rolling to smooth the surface (as opposed to compacting it)

- The amount of wear in the pitching area

- The moisture content (and its effect on the soil strength).

Friction between ball and surface is determined by:

- Grass cover

- The moisture content of the leaf (green leaves tender to carry more moisture than brown/beige grass).

- The condition of the ball and its seam, and the way the seam interacts with the surface during impact.

- The smoothness of the surface (see above).

These factors determine the performance of the pitch where the ball lands – so for consistent pace, bounce, seam and spin we need consistent hardness, smoothness, and friction. It is not all about how much, but also how uniform – this is where the role of the grounds manager is critical – whatever is done to maximise hardness and smoothness and to optimise ball-surface friction, needs to be done consistently across the pitching area of the pitch at each end of the pitch.

How to adjust pitch performance

|

Pitch Performance Problem |

What to change |

What happens when you change it too much |

|

Slow pace |

Increase your height of cut and brush the grass frequently. Roll grass in on final pass. Leave more grass in your pitch. |

This can cause the pitch to seam more favouring bowler over batter. It can lead to variable bounce if the grass is not brushed, or grass cover is uneven. |

|

Excessive pace (e.g., for age group) |

Reduce height of cut. Thin the sward to reduce the number of grass plants. Dry the pitch (decrease moisture content) using covers and/or by starting pitch preparation two days sooner. |

Removing too much grass will mean that the pitch wears more quickly and could spin more earlier in the game. |

|

‘Two-paced’ pitch |

The term ‘two-paced’ is often used by batters to describe a pitch where two balls of similar length delivered at the same pace by the same bowler will either bounce at different heights or come off the surface at different speeds. True two-paced pitches are often characterised by:

The key to managing two-paced pitches is trying to do everything the same. Water evenly – soaker hoses or water tractors might provide more even wetting than hand watering for example. Fix holes in covers and stop water running under covers (see guide on covering pitches here). Roll, brush and cut evenly across the playing area. If you can, start to build regular Verti-cutting into your maintenance of the square and pitch preparation – this will help to manage grass density. Always carry out a full end of season renovation to remove unwanted grasses and establish a uniform sward. Try to maintain a 20-25 mm height of cut through the winter when conditions allow to keep a uniform, dense sward from renovation into the season. |

|

|

Low ball bounce |

There are e three things to consider with ball bounce:

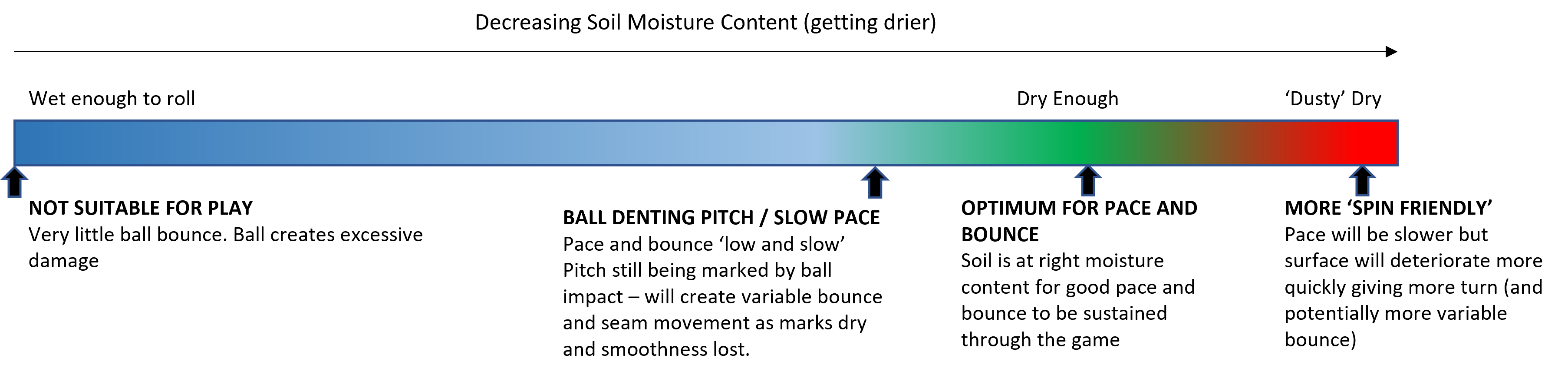

Is your pitch hard enough? – Try pushing a sharp object such as Philips No 1 screwdriver (Posidrive No 1 is an ok too!) into the pitch. Is it hard work (your pitch is ok) or is it easy and soft (you need to make your pitch harder). If the soil is wet, then the pitch needs to dry more. If the pitch is dry but soft, then it needs to be wetted more initially in the prep process and rolled more. The soil may appear dry on the surface, but if it is too wet underneath then efforts need to be made to achieve a deeper drying (usually this means relying on the grass plant to draw deep moisture out during the conditioning phase, so consider keeping a higher cut height during preparation) Use a combination of drying and rolling in batches of four passes over a number of days to get the pitch harder. Try to cover when it is raining and uncover when it is not. If your pitches are very dry, slow the rate of drying using covers. Very dry pitches can also reduce bounce so do not over dry. Does your square have a thatch layer in the surface of the profile – see PitchPower App for how to test this. You will need to remove this thatch over time using scarification – it is a thick layer of thatch (>5 mm) you might need to resurface your square – speak to your County Pitch Advisor on how this is done. If it is a used pitch, it might be time for a fresh one. |

Your pitch cannot really be too hard.

You should aim to minimise thatch and zero-thatch is the ultimate aim. You can cause problems with scarification in-season (see here for best practice). |

|

Slow, high ball bounce (‘tennis ball bounce’) |

This is typically caused by a pitch which is soft but is deforming causing the ball to rise steeply but slowly. It can also occur in dry-cracking pitches if the cracks are unstable. Make sure your pitches are dry enough so that they don’t damage during ball impact. If your pitches are cracking, you can slow the rate of drying with covers or with very light watering (but not within 2 days of play). |

|

|

Uneven bounce |

This is typically caused by a pitch which is soft but is deforming causing the ball to rise steeply but slowly. It can also occur in dry-cracking pitches if the cracks are unstable. Make sure your pitches are dry enough that they don’t damage during ball impact. If your pitches are cracking, you can slow the rate of drying with covers or with very light watering (but not within 2 days of play). Sometimes uneven bounce is caused by uneven grass distribution (see ‘two-paced’ pitches above). It is more common in used pitches and it might be time to start on a fresh one. For information on how to get the most out of used pitches – see here. |

|

|

Excessive seam |

It is likely that your pitch has excessive grass content – in particular too much lush, moist green grass, or excessive horizontal growth, or it may be damp around the grass leaves. |

|

|

Insufficient seam |

This is actually a rare complaint – particularly in recreational cricket. However if required, you can increase the amount of seam by:

|

Excessive seam can favour the ball over the bat in many circumstances. Be aware also that it is likely to persist through both innings in a limited overs match. |

|

Excessive spin |

Excessively spinning pitches are often characterised by very dry, worn, rough or with uneven coarse grass content; anything that makes the surface variable and with increased friction between surface and ball. This is more common in used pitches but can be caused in the preparation phase. To correct excessive spin, maintain more moisture in the pitch (but not excessive moisture), retain more grass leaf and improve surface smoothness by wetting and rolling the pitch correctly (see Pitch Preparation guide here). Top dressing effectively during end of season renovation and carrying out pre-season rolling can all help with improving surface smoothness. Finally, it could be that your pitch is too worn and that fresh one is required. |

|

|

Insufficient spin |

Insufficient spin, is the reverse of excessive spin – see ‘Excessive Spin’ above. Good pitch preparation of first-use pitches tends to reduce spin because of increased grass content. |

|

|

Pitch wears too quickly |

A fast wearing pitch is often caused by three factors:

The principal solution to low binding strength is to reconstruct the square with a higher binding strength/clay content loam but this is expensive and disruptive. Avoid over-drying lower clay content loams as this reduces their shear strength. Weak, shallow rooted grasses, in particular annual meadow grass (Poa annua). This is the main cause of high wear. Annual meadow grass (Poa annua) is shallow rooting (roots often within top 20-30 mm of the profile) and is therefore weakly anchored in the soil which makes it more susceptible to wear and ‘kicking out’ compared to a perennial ryegrass plant which roots more deeply in the soil. Annual meadow grass content can be reduced through scarification, and an effective end-of-season renovation is essential; both to remove annual meadow grass but also to increase the perennial ryegrass content. Effective spiking can help to increase root depth and therefore wear resistance. Make sure your square receives sufficient nutrients from fertiliser. Be aware that excessive nitrogen application can weaken the grass plant, so a lower-N, higher potassium, iron, magnesium containing fertilisers can be more appropriate for maintaining plant strength. |

|

Tweet

Tweet